Print & cut in Germany

hmiadadmin2024-03-05T05:32:06+01:00Print and Cut in Germany

About Print and cut

'' Print & cut in Germany ''

“Print and cut” is commonly used in the graphic design and printing industry to describe a technology and process. This process involves printing a design on a material, such as paper or vinyl, and then precisely cutting it into a specific shape or outline. Print and cut technology is widely utilized for various applications, including signages, labels, decals, stickers, and promotional materials. Here is an overview of the print and cut process:

Printing:

The process begins with either creating or selecting a design. The design is then digitally printed onto a material using a specialized printer. Depending on the material and the desired quality, common printing technologies include inkjet, laser, or other digital printing methods.

Cutting and Plotting:

Once the printing is finished, the material with the printed design is fed into a cutting machine. This machine is equipped with a cutting tool, such as a blade or a laser, which follows a predetermined cutting path based on the design.

Cutting Lines and registration lines:

To ensure accuracy, registration marks are often incorporated into the design. These marks serve as reference points for the cutting machine to align and adjust the cutting process according to the printed design.

Digital Control:

The entire print and cut process is typically controlled by computer software. This software interprets the digital design file, coordinates the printing and cutting actions, and ensures that the final product matches the intended design accurately.

Applications:

Print and cut technology is extensively utilized in various industries to create custom and accurately cut graphics. Some typical applications include:

- Signage: Customized signs with intricate shapes and designs can be produced using this technology.

- Labels: It is used in the production of labels for products or packaging.

- Decals and Stickers: This technology enables the creation of promotional or decorative decals and stickers.

- Textile and Apparel: Specific designs can be achieved through heat transfers and fabric appliqués.

- Vehicle Graphics: Graphics for vehicles, including wraps and decals, can be designed and produced using print and cut technology.

Materials:

Print and cut technology is versatile and can be applied to a variety of materials such as paper, vinyl, fabric, and more. The choice of material depends on the specific application and desired end result.

Advantages:

The key advantages of print and cut technology are precision and customization. It allows for the production of intricate and complex designs with utmost accuracy, making it an invaluable tool for industries where detailed graphics and precise shapes are essential.

Versatility:

Print and cut machines are available in various sizes and capabilities, with different brands catering to a wide range of applications. Small desktop machines are suitable for office or small-scale production, while larger industrial machines are utilized for high-volume and large-format projects.

Image source is Wikipedia: Digital Printing

Print and Cut

We offer print and cut services for branding, making stickers, T-shirt and textile printing, and many other products at HMi!

Die-Cutting vs. Print and Cut:

Although both die-cutting and print and cut processes involve cutting materials into specific shapes, they have different methods. Die-cutting uses a physical die or mold to cut materials, while print and cut is a digital process that combines printing and cutting in a single workflow.

Print and cut provides more flexibility and is particularly beneficial for complex and customized designs.

Variable Data Printing:

Apart from static designs, print and cut technology can be utilized for variable data printing. This allows each printed piece to contain unique information, such as serial numbers, barcodes, or personalized text. This is advantageous for applications like product labeling or personalized promotional materials.

Prototyping and Short Runs:

Print and cut technology is perfect for prototyping and producing short runs of customized items. It enables businesses to test designs, create small batches of products, or quickly respond to changing marketing needs without the high costs associated with traditional printing and cutting methods.

3D Printing and Cutting:

Certain advanced print and cut machines have the ability to produce three-dimensional objects by combining 3D printing with cutting. This is particularly valuable in industries such as packaging, where unique and creatively shaped packaging can be manufactured in a single process.

Specialized Applications:

Print and cut technology is utilized in specialized applications, such as creating decals for outdoor use (with weather-resistant materials), heat transfers for textile applications (like custom apparel or fabric printing), and intricate designs for artistic projects.

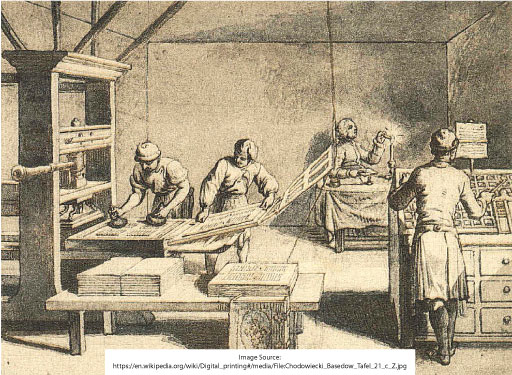

The history of printing and Cutting

The origins of printing can be traced back to ancient civilizations, where early techniques like woodblock printing and movable type printing were employed.

However, it took time for technology to advance and enable the accurate reproduction and cutting of intricate designs.

A significant milestone in the evolution of print and cut technology occurred in the mid-20th century with the introduction of pen plotters. These innovative devices utilized pens to draw digital instructions on paper or other materials. Although not strictly printing, pen plotters laid the groundwork for more sophisticated technologies to come. The latter half of the 20th century witnessed a crucial development in print and cut systems with the emergence of digital printing technologies like inkjet and laser printing.

These advancements allowed for more precise and versatile reproduction of designs, marking a significant leap forward in the field. In the 1980s, cut plotters, also known as vinyl cutters, started gaining popularity. These machines utilized a computer-controlled blade to cut vinyl sheets into precise shapes. Initially, they were standalone devices primarily used for creating signage, lettering, and decals.

Print and cut in Germany

We offer different printing methods and printing solutions at HMi. We offer professional printing methods to offer you all of your branding and marketing products all in one place with top quality and prices in Germany.

Printing products and branding promotional gift items was never easier than today, as we offer all in one marketing services and products to our clients. If you are looking for a professional company who can help your brand to grow with marketing ideas and giveaways, HMi is your only solution in Germany.

Printing in Germany – print and cut in Germany – Printing services in Germany – Professional Print and cut services for branding in Germany at HMi – HMi offers printing services along with cutting and plotting services with fast turnover – Printing online in Germany – Print and cut in Bochum – Print and cut in Dusseldorf – Print and cut in Dortmund – Print and cut in Cologne – Print and cut in Bonn with top quality with HMi – HMi offers professional Printing services with fast turnover and free graphic design services in Germany – Print and cut on Berlin – Print and cut in Hamburg – Print and cut services Frankfurt – Printing in Dusseldorf – Printing Services in Germany with top prices and professional graphic design services on hmi-ad.com – Print and cut in Stuttgart – Professional Printing products and branding services in Dusseldorf with Print and cut systems at HMi